Polyreflex is a professional manufacturer with more than 15 years experiences, with five production sites located in China and one production site located in Vietnam.

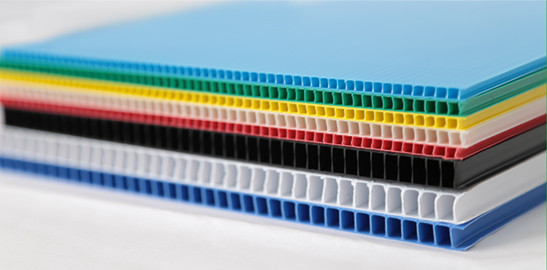

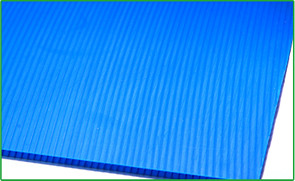

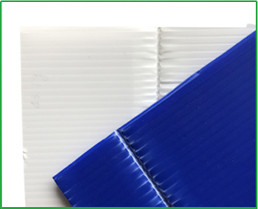

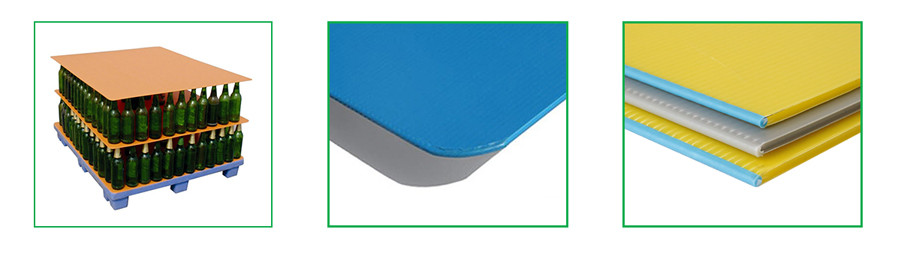

Waterproof Lightweight Plastic PP Corrugated Corflute Sheet for Floor Protection

Sheet

Waterproof

Lightweight

Recyclable

Polypropylene (PP) copolymer, homopolymer resin and some fillers.

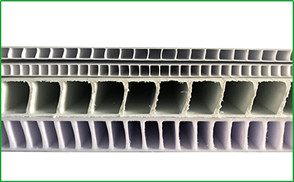

It is an extruded corrugated sheet consisting two flat walls

connected by vertical ribs, or in the pozidrive structure. PP

corrugated sheet is absolutely harmless and odourless, and

moisture resistance & anticorrosion. Its special and great

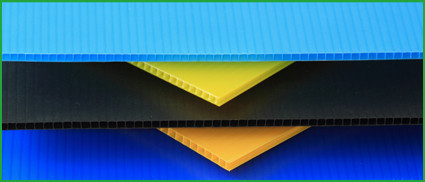

properties such as strong, lightweight, various colors make it

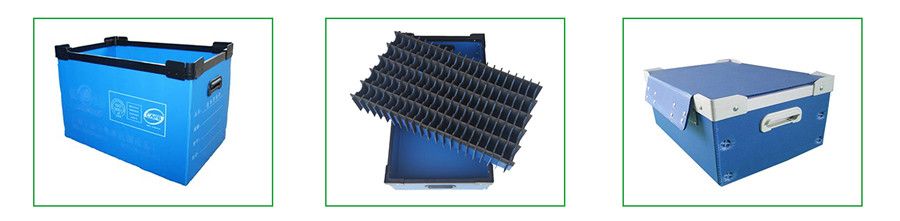

good in packaging, advertising, construction, agriculture and

industry uses.

- High Stability, Easy Finishing, Largely Chemical Resistant

- Non-toxic, Pollution-free, Environment Protection

- Strong Toughness, Good Bending Performance

- Waterproof, Dampproof and Weather Resistant

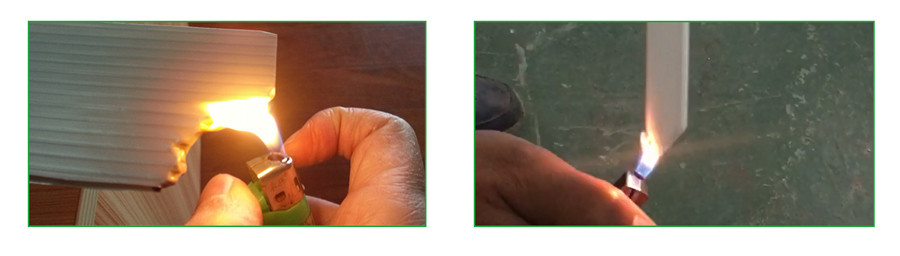

- Light Weight, Fire Resistance and Low Cost

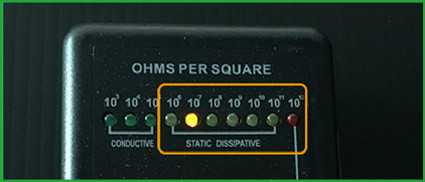

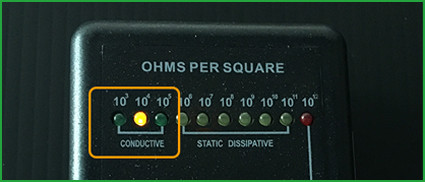

- Anti-static, Electric Conduction

- Corrosion and Rot Resistant

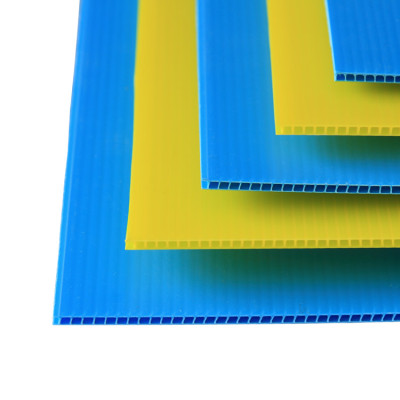

| Thickness: | 1.5-14.6mm | ||||||||||||||||||||

| Width: | 1000, 1220, 2000mm are standard. Max.width is 2400mm. Other width can be customized. | ||||||||||||||||||||

| Size: | 1000x2000mm, 1200x2400mm, 1220x2440mm are standard. Other size can be customized. | ||||||||||||||||||||

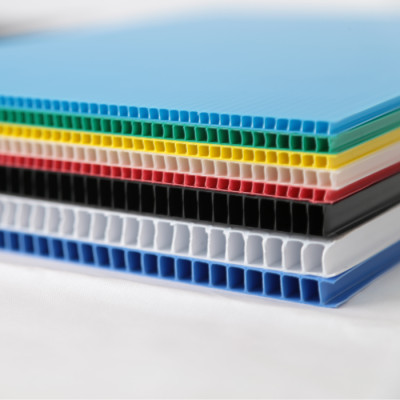

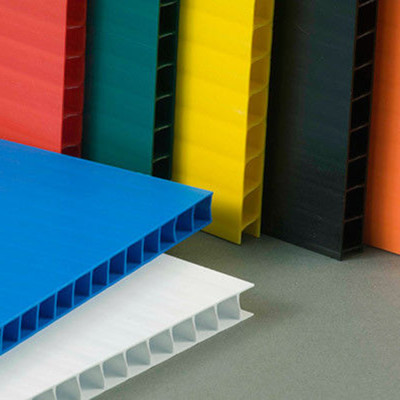

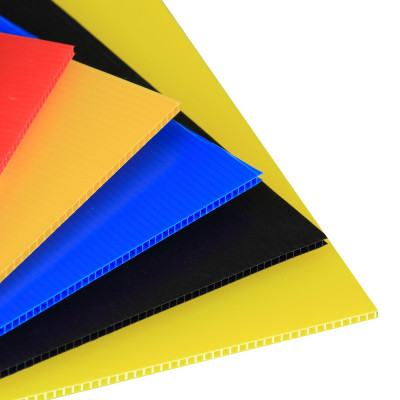

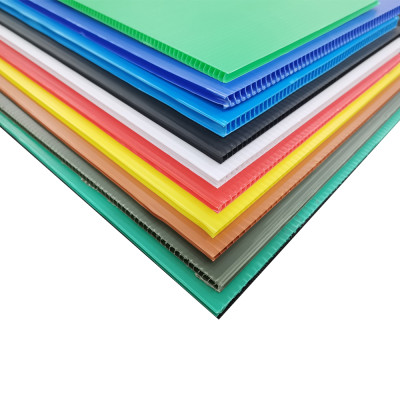

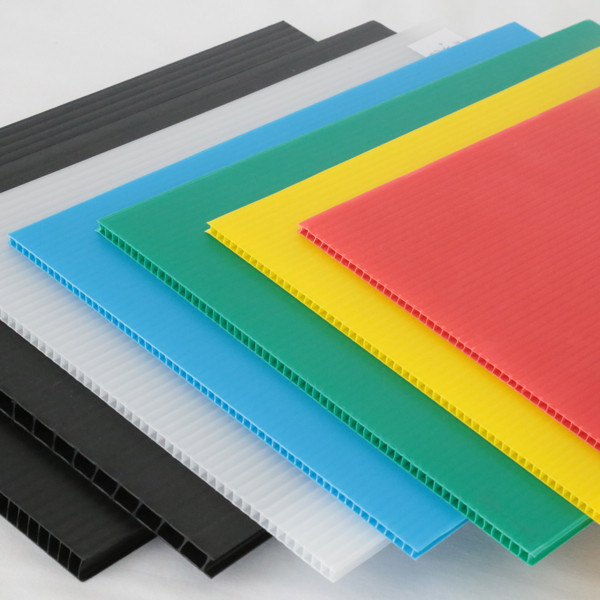

| Colour: | White, Black, Grey, Red, Yellow, Green, Blue, Brown are standard. Other colors can be customized according to RAL / Pantone. | ||||||||||||||||||||

| Surface: | Smooth, Matt, or very flat | ||||||||||||||||||||

| Weight: | 180-4000gsm | ||||||||||||||||||||

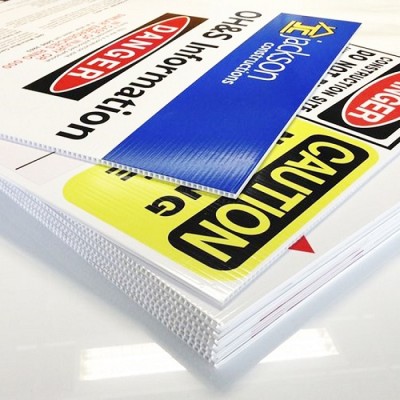

| Printing: | Available with all kinds of design. | ||||||||||||||||||||

- Are you a trading company or a manufacturer?

- more>

- Can you cut to size or print or thermoform?

- more>

Of course we can. Polyreflex processing center has a variety of advanced processing equipment, and a well-trained and experienced technical team to meet the customized needs of customers, such as cutting, machining, vacuum forming, injection molding, blow molding, assembly, etc.

- What is the payment method?

- more>

T/T, L/C, PayPal, Western Union payment are available. Polyreflex is an Alibaba certified supplier, and it is also okay to place an order through Alibaba. https://polyreflex-cn.en.alibaba.com/

- What is the lead time?

- more>

Usually 15 to 20 days. The specific lead time is best to be confirmed after letting us know the order details. We have stock of plastic sheets to meet urgent needs, and we can also advance the delivery time for customers according to the production condition.

- Name

- *Title

- *Content

- Name:

- Helen G

- Tel:

+0086-759-3320922

- Email:

- sale@polyreflex.com

- WhatsApp:

- 8613828266785

- Address:

- Shuilang Industrial Zone, Dalingshan Town, Dongguan, Guangdong, China