Polyreflex is a professional manufacturer with more than 15 years experiences, with five production sites located in China and one production site located in Vietnam.

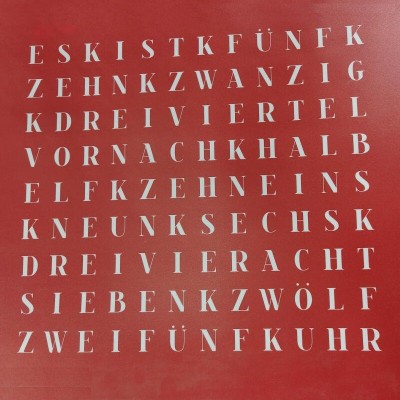

Non-toxic, Tasteless, Waterproof, Low Density, Rigid Plastic PP Polypropylene Sheet

Durable

Waterproof

Offset printing

tasteless, waterproof, low density, very rigid plastic material, which

could offer high impact strength, high wear resistance, wide

temperature stability range from -20oC to 120oC. which has good

chemical stability . It could be easily offset printed, silk-screen

printed, die-cut, bent etc, and it is widely used for stationery,

food packing, Cartoon characters.

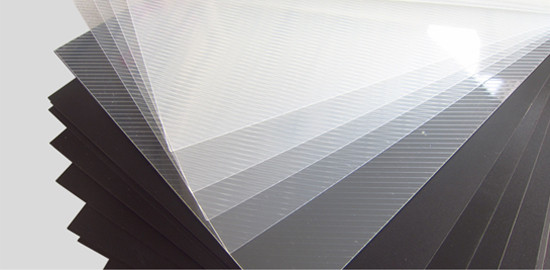

- Suitable for offset printing, silk-screen printing

- Good heat-resistant performance(+120°C)

- Low moisture absorbability, non-toxic

- Excellent electrical insulation

- Good abrasion resistance

- High impact strength

- Excellent formability

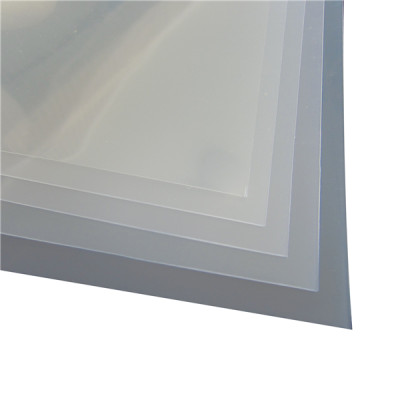

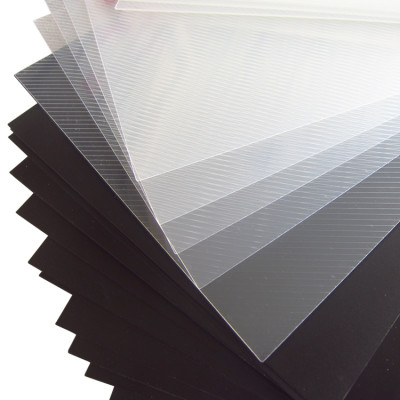

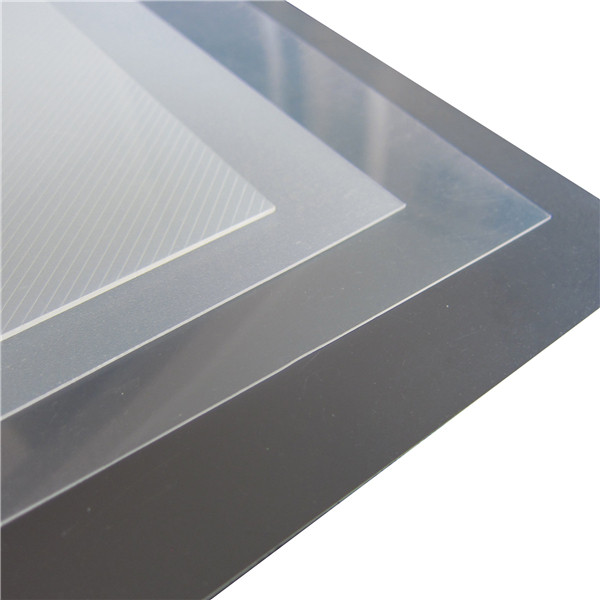

| Thickness: | 0.15-2mm |

| Width: | Max.1100mm |

| Size: | B5, A4, A3, A2, A1 or other size can be customized |

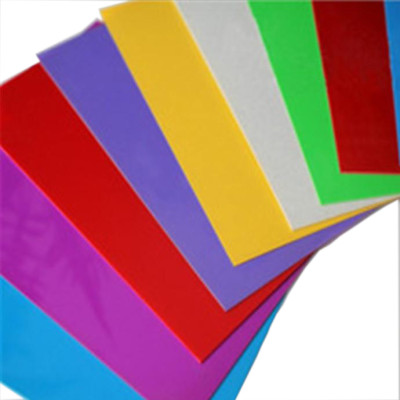

| Colour: | Solid white, Natural, Black, Grey, Geen, Blue, Red, Yellow are standard. Other colors can be customized according to RAL / Pantone |

| Surface: | Smooth and texture |

| Weight: | 0.91-0.96g/cm3 |

| Service options: | Offset printing, silk-screen printing |

- Are you a trading company or a manufacturer?

- more>

- Can you cut to size or print or thermoform?

- more>

Of course we can. Polyreflex processing center has a variety of advanced processing equipment, and a well-trained and experienced technical team to meet the customized needs of customers, such as cutting, machining, vacuum forming, injection molding, blow molding, assembly, etc.

- What is the payment method?

- more>

T/T, L/C, PayPal, Western Union payment are available. Polyreflex is an Alibaba certified supplier, and it is also okay to place an order through Alibaba. https://polyreflex-cn.en.alibaba.com/

- What is the lead time?

- more>

Usually 15 to 20 days. The specific lead time is best to be confirmed after letting us know the order details. We have stock of plastic sheets to meet urgent needs, and we can also advance the delivery time for customers according to the production condition.

- Name

- *Title

- *Content

- Name:

- Helen G

- Tel:

+0086-759-3320922

- Email:

- sale@polyreflex.com

- WhatsApp:

- 8613828266785

- Address:

- Room 1807, Phase 3 Cuidiwan, No.2 Junmin Rd, Zhanjiang, Guangdong, China