Polyreflex is a professional manufacturer with more than 15 years experiences, with five production sites located in China and one production site located in Vietnam.

plastic pp countertops companion table top board desk plate material

Lightweight

Easy Bonding

High Strength

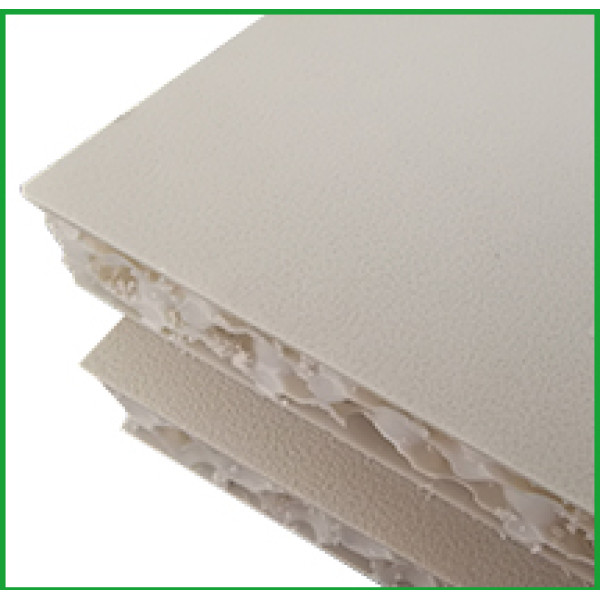

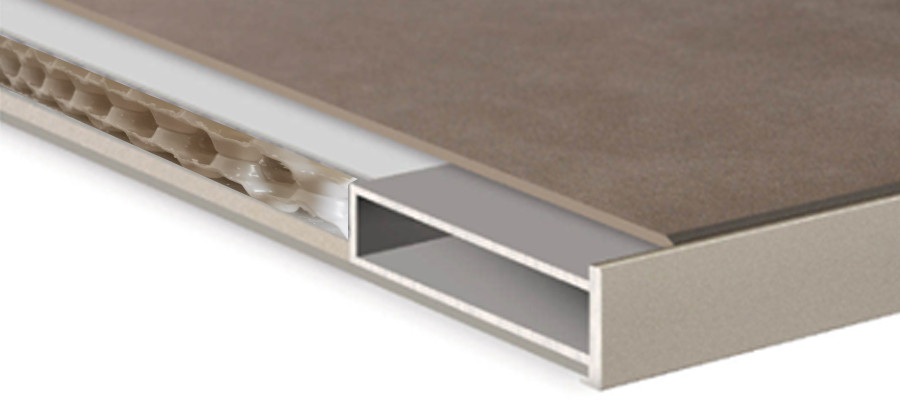

smart honeycomb structure, through technical innovation and without using

any glue, the four layers of polypropylene are closely bonded together and

have smooth surface . It's made by PP the even food contact material, so the

board is fully safely and environmental friendly. Because of its unique

honeycomb structure, plus the characteristics of PP material itself, the

construction honeycomb has the advantages of light weight and high

strength.It's very ideal board to use as the base panel under quartz stone,

porcelain slab, so we also call it Countertops Companion. Besides the

application use as base panel, it can also use as wall panel, partition, etc.

- Light Weight - Approx. 50% Lighter Than Wood

- Dimension Stability and Waterproof

- Excellent Compression Strength

- Easy to Bond to Other Materials

- Excellent Surface Appearance

- Corrosion and Rot Resistant

- Largely Chemical Resistant

| Thickness: | 15,20,25,29mm | ||||||||||||||||||||

| Width: | 550, 1100 are standard. Max. width is 1400mm. Other width can be customized. | ||||||||||||||||||||

| Size: | 550*3000mm, 1100*3000mm are standard. Other size can be custommized. | ||||||||||||||||||||

| Colour: | Grey White is standard. Other colors like drak grey can be customized. | ||||||||||||||||||||

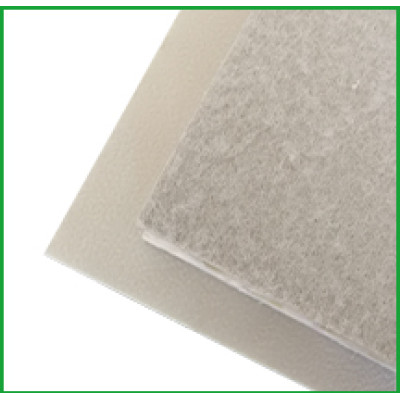

| Surface: | Rough & matt, Rough & Fabric. | ||||||||||||||||||||

| Weight: | 3200, 3400, 3700, 3800, 4200 and 4700 | ||||||||||||||||||||

Flatten Boards

Nail-free Glue

with Load on it

- Are you a trading company or a manufacturer?

- more>

- Can you cut to size or print or thermoform?

- more>

Of course we can. Polyreflex processing center has a variety of advanced processing equipment, and a well-trained and experienced technical team to meet the customized needs of customers, such as cutting, machining, vacuum forming, injection molding, blow molding, assembly, etc.

- What is the payment method?

- more>

T/T, L/C, PayPal, Western Union payment are available. Polyreflex is an Alibaba certified supplier, and it is also okay to place an order through Alibaba. https://polyreflex-cn.en.alibaba.com/

- What is the lead time?

- more>

Usually 15 to 20 days. The specific lead time is best to be confirmed after letting us know the order details. We have stock of plastic sheets to meet urgent needs, and we can also advance the delivery time for customers according to the production condition.

- Name

- *Title

- *Content

- Name:

- Helen G

- Tel:

+0086-759-3320922

- Email:

- sale@polyreflex.com

- WhatsApp:

- 8613828266785

- Address:

- Room 1807, Phase 3 Cuidiwan, No.2 Junmin Rd, Zhanjiang, Guangdong, China