Polyreflex is a professional manufacturer with more than 15 years experiences, with five production sites located in China and one production site located in Vietnam.

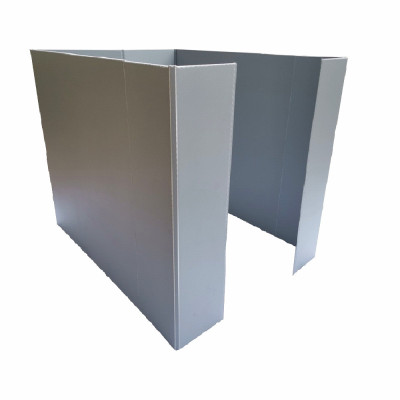

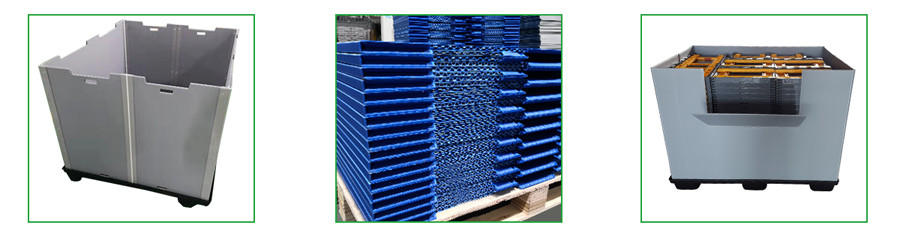

Lightweight Durable Heavy-duty PP Honeycomb Pallet Sleeve System Packs Box

800*600

1100*1100

1140*980

1150*1150

1200*800

1200*1000

1220*1140

1350*1150

1470*1150

1600*1150

2070*1150

molded bulk boxes. Use them for closed loop material handling and

as returnable and reusable bulk packaging. Their unique

construction makes them the strongest pallet sleeves in the

industry. It can save the transportation cost up to 40%-80% by the

recycled use of both lining and box.

- Non-bowing Maximum strength in all directions

- Base and cover Easy to fold flat for space saving

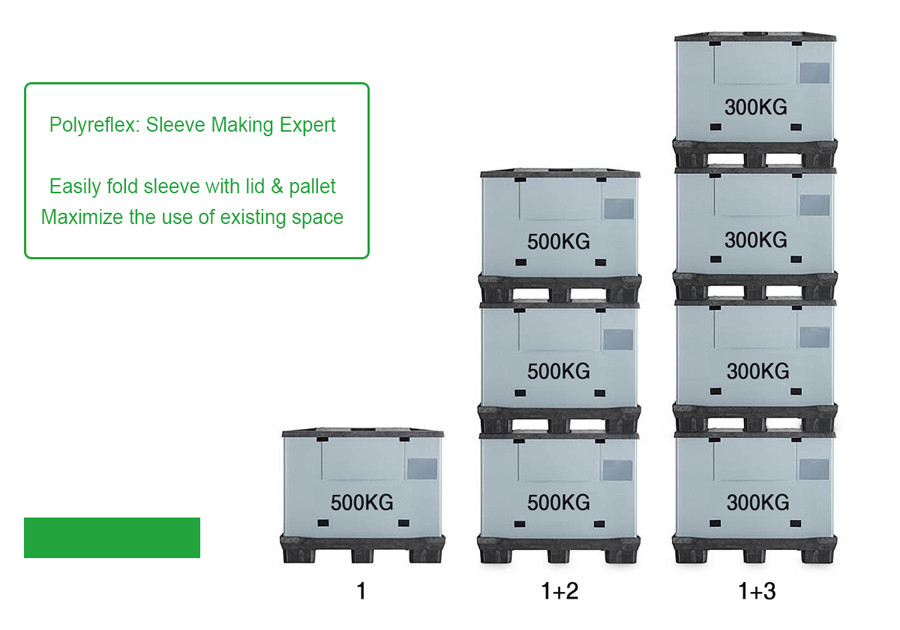

- Easy to assemble Stackable when used with pallet

- No V.O.C. Emissions Eco-friendly - 100% recyclable

- Nontoxic & Hypoallergenic Storage or return shipment

- Resistant to chemical agents Light weight & waterproof

- Printable in many colors

| PR 0806 H 700 | PR 1111 H 900 | PR 1140 H 900 | PR 1150 H 900 | PR 1208 H 900 | PR 1210-3 H 1000 | PR 1210-8 H 1000 | PR 1220 H 1000 | PR 1350 H 1000 | PR 1470 H 1000 | PR 1600 H 1000 | PR 2070 H 1000 | |||

| Material | Pallet | Twin-sheet HDPE | ||||||||||||

| Reinforced | - | - | - | - | - | - | Steel Rod Reinforced | - | - | - | - | - | ||

| Lid | Twin-sheet HDPE | |||||||||||||

| Sleeve | PP - 10mm - 3000g | PP Fiber-glass Reinforced - 11mm - 4000g | PP - 10mm - 3000g | PP -11mm -3500g | ||||||||||

| Weight in KG | Tare | 17 | 31 | 30 | 32 | 29 | 33 | 56 | 38.5 | 40 | 44 | 52 | 61 | |

| Payload | 200 | 300 | 300 | 300 | 280 | 300 | 800 | 300 | 300 | 300 | 300 | 300 | ||

| Max Ballast | 800 | 1200 | 1200 | 1200 | 1120 | 1200 | 1600 | 1200 | 1200 | 1200 | 1200 | 1200 | ||

| Stack Layer | Static | 1+3 | 1+3 | 1+3 | 1+3 | 1+3 | 1+3 | 1+1 | 1+3 | 1+3 | 1+3 | 1+3 | 1+3 | |

| Dynamic | 1+1 | 1+1 | 1+1 | 1+1 | 1+1 | 1+1 | 1+1 | 1+1 | 1+1 | 1+1 | 1+1 | 1+1 | ||

| Dimension in mm | Outside | L | 800 | 1100 | 1140 | 1150 | 1200 | 1200 | 1200 | 1220 | 1350 | 1470 | 1600 | 2070 |

| W | 600 | 1100 | 980 | 1150 | 800 | 1000 | 1000 | 1140 | 1150 | 1150 | 1150 | 1150 | ||

| H | 700 | 900 | 900 | 900 | 900 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | ||

| Inside | L | 760 | 1060 | 1100 | 1110 | 1160 | 1160 | 1160 | 1180 | 1310 | 1430 | 1560 | 2030 | |

| W | 560 | 1060 | 940 | 1110 | 760 | 960 | 960 | 1100 | 1110 | 1110 | 1110 | 1110 | ||

| H | 520 | 720 | 720 | 720 | 720 | 820 | 820 | 820 | 820 | 820 | 820 | 820 | ||

| Folded | L | 800 | 1100 | 1140 | 1150 | 1200 | 1200 | 1200 | 1220 | 1350 | 1470 | 1600 | 2070 | |

| W | 600 | 1100 | 980 | 1150 | 800 | 1000 | 1000 | 1140 | 1150 | 1150 | 1150 | 1150 | ||

| H | 238 | 238 | 238 | 238 | 238 | 238 | 238 | 238 | 238 | 238 | 238 | 238 | ||

| Remark: Sleeve size can be customized according to your request if you have your own pallet/lid system, and gsm of pp honeycomb panel can be produced from 2500-4000gsm accroding to your design. | ||||||||||||||

- Are you a trading company or a manufacturer?

- more>

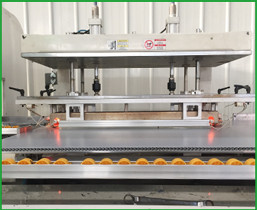

- Can you cut to size or print or thermoform?

- more>

Of course we can. Polyreflex processing center has a variety of advanced processing equipment, and a well-trained and experienced technical team to meet the customized needs of customers, such as cutting, machining, vacuum forming, injection molding, blow molding, assembly, etc.

- What is the payment method?

- more>

T/T, L/C, PayPal, Western Union payment are available. Polyreflex is an Alibaba certified supplier, and it is also okay to place an order through Alibaba. https://polyreflex-cn.en.alibaba.com/

- What is the lead time?

- more>

Usually 15 to 20 days. The specific lead time is best to be confirmed after letting us know the order details. We have stock of plastic sheets to meet urgent needs, and we can also advance the delivery time for customers according to the production condition.

- Name

- *Title

- *Content

- Name:

- Helen G

- Tel:

+0086-759-3320922

- Email:

- sale@polyreflex.com

- WhatsApp:

- 8613828266785

- Address:

- Room 1807, Phase 3 Cuidiwan, No.2 Junmin Rd, Zhanjiang, Guangdong, China