Polyreflex is a professional manufacturer with more than 15 years experiences, with five production sites located in China and one production site located in Vietnam.

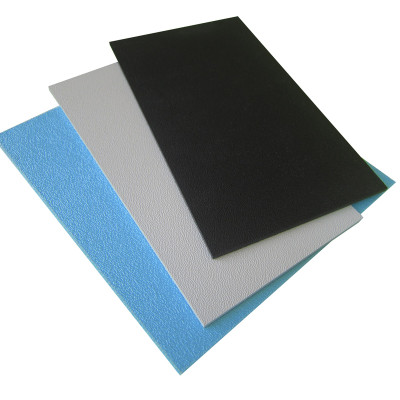

Excellent Formability & High Impact Strength Plastic ABS Sheet for Luggage Case

More stronger, stiffer

Resistance to high temperature

Corrosion & Chemical resistance

thermo-plastic and is formed by the polymerization of styrene and acrylonitrile

on the thermoplastic rubber which is then melt compounded with styrene

acrylonitrile. It is a polymer with the largest output and widest application

scope, has made all properties of PS, SAN and BS dynamically integrated,

which has excellent mechanical properties with harmony of toughness,

hardness and rigidity.

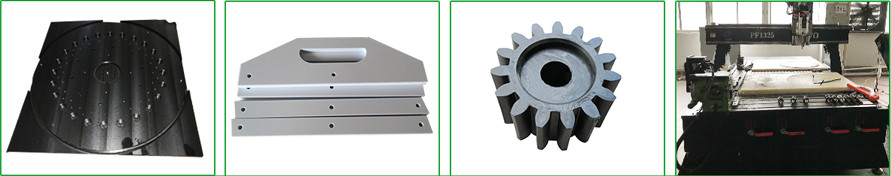

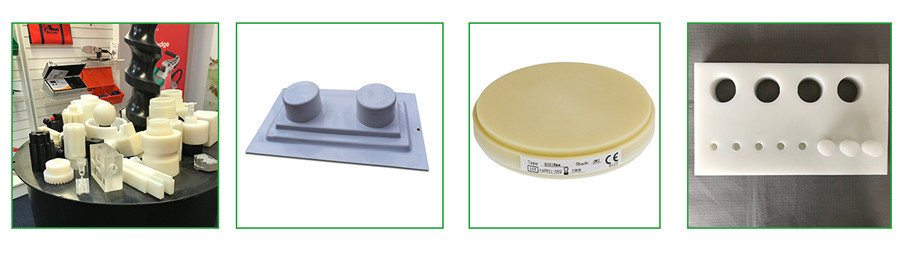

It can be laser/CNC cutting or vacuum thermoforming, widely used in

automotive interior and exterior, aircraft interior trims, lab equipment,

luggage, office accessories, toys, machine parts and rollers.

- Good Dimension Stability, Dyeing, Molding and Machining

- Excellent Chemical and Corrosion Resistance

- High Impact Toughness, Good Inoxidizability

- Excellent Formability; Easily Electroplated

- Excellent Weathering Resistance

- Low Water Absorption, Non-toxic

- Excellent Electrical Insulation

- Good Abrasion Resistance

- High Mechanical Strength

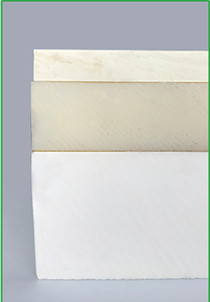

Quality is shown in detail

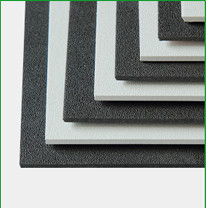

| Thickness(mm): | 0.8-2.5 | Size:1000*2000, 915*1830, 1220*2440 are popular to produce, other size can be customized. |

| 3-25 | Size: 1000*2000 in stock, other size can be customized. | |

| 30-100 | Size: 1000*1220mm in stock, other size can be customized. | |

| 105-230 | Size: 1000*2000mm in stock, other size can be customized. | |

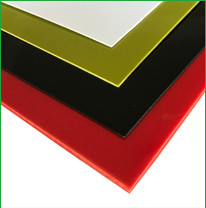

| Colour: | Natural, Black are standard. Other colors can be customized according to RAL / Pantone. | |

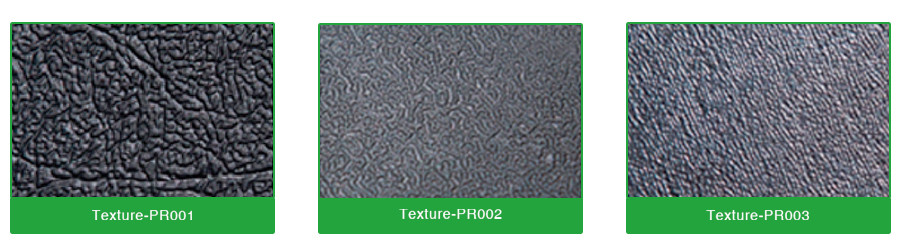

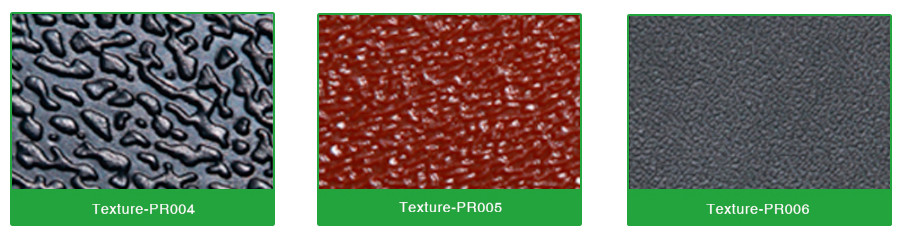

| Surface: | Smooth and texture. | |

| Weight: | 1.06-1.1g/cm3. | |

| Service options: | CNC machined, Vacuum thermoforming. | |

- Are you a trading company or a manufacturer?

- more>

- Can you cut to size or print or thermoform?

- more>

Of course we can. Polyreflex processing center has a variety of advanced processing equipment, and a well-trained and experienced technical team to meet the customized needs of customers, such as cutting, machining, vacuum forming, injection molding, blow molding, assembly, etc.

- What is the payment method?

- more>

T/T, L/C, PayPal, Western Union payment are available. Polyreflex is an Alibaba certified supplier, and it is also okay to place an order through Alibaba. https://polyreflex-cn.en.alibaba.com/

- What is the lead time?

- more>

Usually 15 to 20 days. The specific lead time is best to be confirmed after letting us know the order details. We have stock of plastic sheets to meet urgent needs, and we can also advance the delivery time for customers according to the production condition.

- Name

- *Title

- *Content

- Name:

- Helen G

- Tel:

+0086-759-3320922

- Email:

- sale@polyreflex.com

- WhatsApp:

- 8613828266785

- Address:

- Room 1807, Phase 3 Cuidiwan, No.2 Junmin Rd, Zhanjiang, Guangdong, China