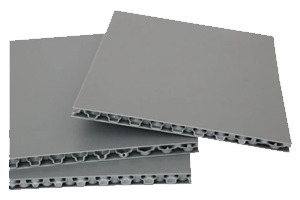

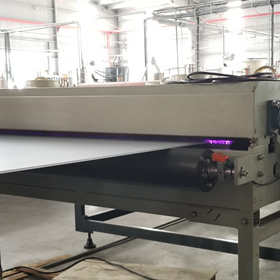

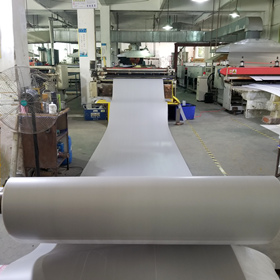

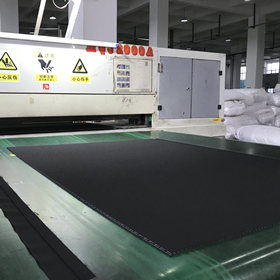

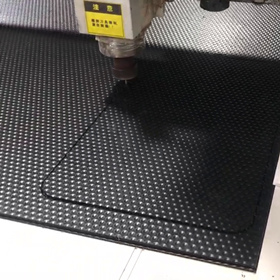

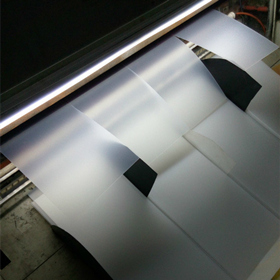

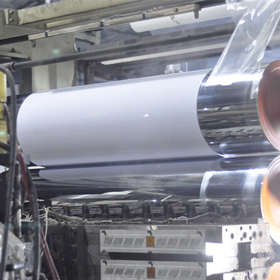

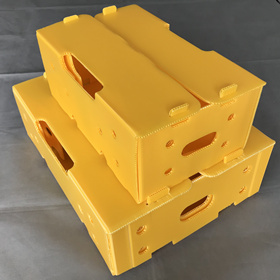

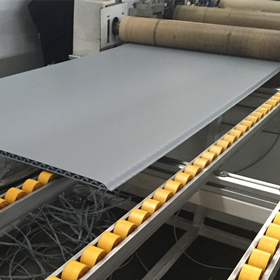

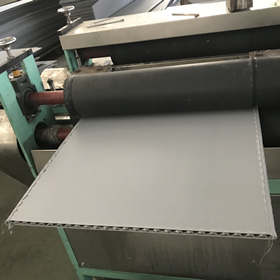

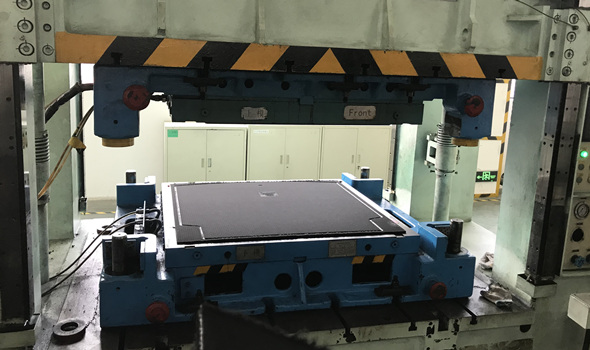

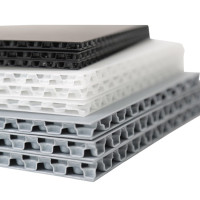

Vietnam plant for PP corrugated sheet

In order to cope with the changing international trade environment, reduce the extra 25% - 35% tariffs of our American customers on importing plastic sheets, Polyreflex built a factory in Vietnam, all goods are exported directly from Ho Chi Minh Port to the United States.