China manufacturer lightweight plastic corrugated sheets for sign and packaging boxes Categories

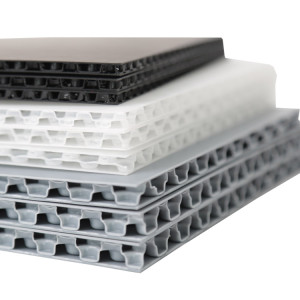

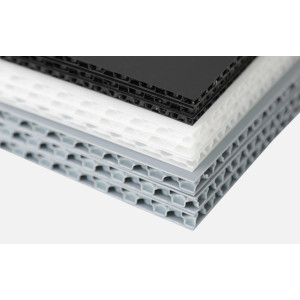

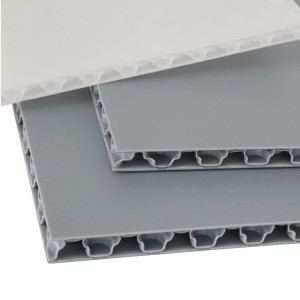

PP Honeycomb Panel

Polyreflex, a leading Chinese manufacturer of PP honeycomb panels, has over 18 years of experience in the production of high-quality polypropylene honeycomb panels. Our panels feature a unique sandwich structure with a honeycomb core, and are available with either a bubble or flat finish on one or both surfaces. The lightweight design, combined with excellent chemical and impact resistance, makes our PP honeycomb panels easy to process, durable, and fully recyclable.

As a trusted supplier, we serve a wide range of industries including automotive, logistics and transportation, warehouse and inventory management, packaging, advertising and display, and construction. At Polyreflex, we are committed to providing our customers with high-performance, reliable, and eco-friendly solutions tailored to meet the demands of diverse applications.

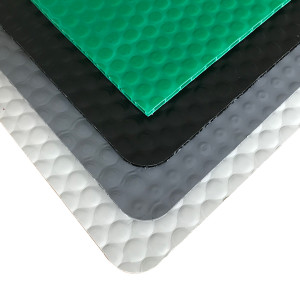

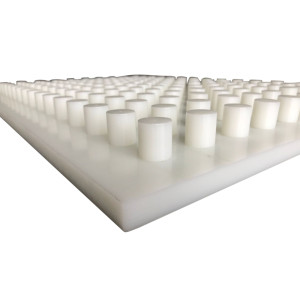

Polypropylene (PP) Bubble Board

Polyreflex, as a leading Chinese manufacturer of PP bubble board, brings nearly 20 years of manufacturing expertise to the production of high-quality polypropylene bubble boards. Our PP bubble board features a lightweight, hollow, triple-wall structure with a cylindrical core and flat, bubble-textured surfaces, offering exceptional durability and versatility. It can also be laminated with non-woven fabric to enhance its functionality, such as for use in spare wheel covers in car trunks.

Known for being environmentally friendly, non-toxic, odorless, flame-retardant, and sound-absorbing, Polyreflex PP bubble board is widely used across the automotive industry. Its applications include luggage liner panels, seat back panels, wall linings, and flooring in vans, SUVs, caravans, and more. With our extensive manufacturing experience, we are proud to be a trusted supplier of high-quality PP bubble board for a variety of industries worldwide.

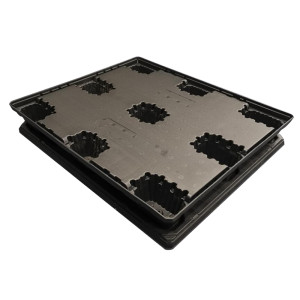

Plastic Pallet Sleeve System

The Polyreflex pallet sleeve container is designed to be durable, returnable, and cost-effective, providing an ideal solution for logistics and material handling systems. It effectively supports, stores, protects, and transports bulk goods or unit loads. Our pallet sleeve system features an all-in-one design, where the top lid, pallet base, and sleeve are combined into a single unit. When empty, the sleeve packs can be collapsed, significantly reducing storage space and ensuring a high return rate of empty containers. This helps reduce transportation costs, as one truckload of folded sleeve packs can replace up to ten truckloads of fully assembled pallet containers with cargo.

As a leading Chinese manufacturer of pallet sleeve containers, Polyreflex offers strong customization capabilities. We can tailor the pallet containers to meet specific project requirements, ensuring that they perfectly fit our customers' needs. Whether it's for size, material, or design modifications, we work closely with our clients to deliver solutions that optimize their supply chain efficiency.

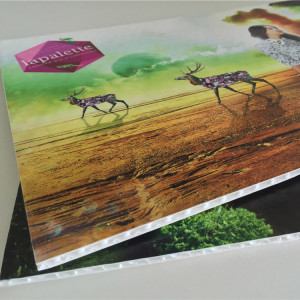

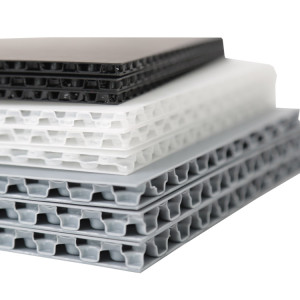

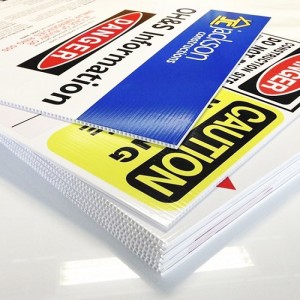

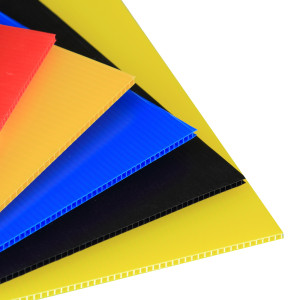

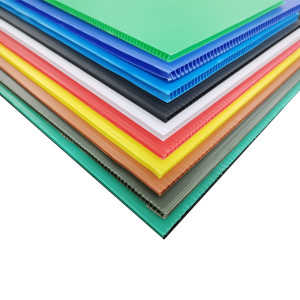

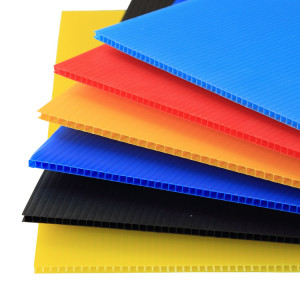

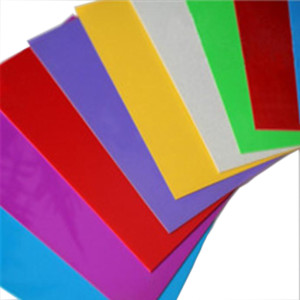

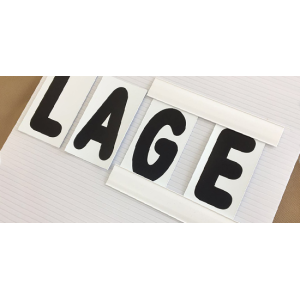

Polypropylene (PP) Corrugated Sheet

Polyreflex PP corrugated sheet is made from a blend of polypropylene copolymer, homopolymer resin, and various fillers. It is also known as twin-wall PP panel, fluted polypropylene sheet, corflute sheet, or coroplast sheet. This material is completely safe, odorless, moisture-resistant, and corrosion-resistant. Thanks to its exceptional properties—such as strength, lightweight, and availability in a wide range of colors—it is widely used in packaging, advertising signage, construction, agriculture, and industrial applications.

As a leading manufacturer of PP corrugated sheets in China, Polyreflex brings over 18 years of expertise in production, offering high-quality PP corrugated sheets to customers worldwide. Our commitment to quality and innovation has established us as a trusted supplier in the industry, delivering durable and reliable products tailored to meet the specific needs of various industries.

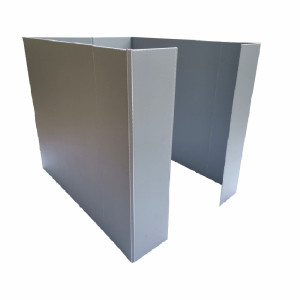

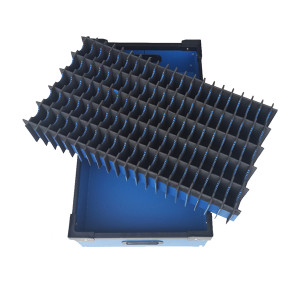

Plastic Box & Divider

Polyreflex, a leading manufacturer of plastic packaging boxes in China, specializes in providing highly customizable packaging solutions. Our plastic boxes and dividers are made from premium PP corrugated sheets or PP honeycomb sheets, reinforced with strengthening agents to ensure superior durability. Designed to be lightweight, durable, reusable, and cost-effective, these packaging solutions offer an ideal way to store, protect, and transport valuable, fragile, or non-waterproof goods, such as electronics, cosmetics, fruits, and beverages. These boxes are perfect for use by distributors, retailers, and end users.

As a versatile manufacturer, Polyreflex excels in custom production, providing tailored plastic boxes that meet the specific requirements of each customer's project. We work closely with clients to design and manufacture packaging solutions that suit their unique needs, ensuring optimal protection and efficiency. In addition to plastic boxes and dividers, we offer a variety of internal protective packaging options, including custom dividers and partitions, foam inserts, dunnage, bags, and wraps. Whether you need simple or highly complex designs, Polyreflex has the expertise and capability to deliver precisely what you require.

ABS Sheet

ABS (Acrylonitrile-Butadiene-Styrene) sheet is an engineering thermoplastic that is widely used in both everyday life and various industries. The popularity of ABS sheet stems from its unique combination of the beneficial properties of three key components: Acrylonitrile, Butadiene, and Styrene. ABS is known for its excellent mechanical properties, offering a balance of toughness, hardness, and rigidity.

The individual characteristics of these components are fully reflected in ABS plastic. Acrylonitrile provides hardness, chemical resistance, and heat resistance. Butadiene contributes to the material’s high elasticity and toughness, while Styrene enhances processability, surface gloss, and electrical properties.

For nearly 20 years, Polyreflex has been a leading manufacturer and wholesaler of ABS plastic sheets and injection-molded ABS products. Our range of ABS sheets includes smooth or textured surfaces suitable for printing or thermoforming, two-color ABS sheets, mechanically reinforced ABS sheets for industrial applications, and composite sheets such as ABS/PMMA and ABS/PC. Additionally, our advanced machining center offers customized processing services, including laser cutting, CNC cutting, and thermoforming of ABS sheets, to meet the specific needs of our customers.

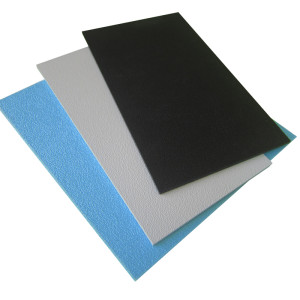

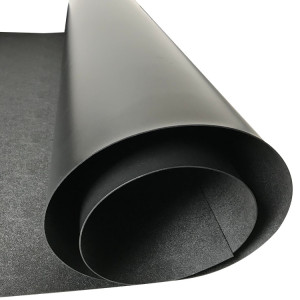

TPO Sheet

Polyreflex's thermoplastic polyolefin (TPO) is a versatile material made from a blend of polyolefins (such as PP or PE), rubber, and various fillers like talc and carbon fiber. As part of the Thermoplastic Elastomer (TPE) family, TPO offers excellent flexibility, impact resistance, and strong chemical resistance. It is also highly durable against UV radiation and extreme temperatures, making it an ideal choice for outdoor applications.

One of the standout uses of TPO sheets is in automotive applications, particularly for car mats and trunk liners. TPO is waterproof, abrasion-resistant, and highly flexible, making it an excellent choice for durable automotive products. Its ease of thermoforming processing also makes it suitable for custom designs, ensuring a perfect fit and long-lasting performance in various automotive applications.

Polyreflex, a leading manufacturer of TPO sheets in China, is proud to offer high-quality TPO sheets tailored to meet the needs of our customers. We possess strong thermoforming capabilities, enabling us to provide custom automotive products that meet specific requirements. Whether you're looking for precision-engineered mats, liners, or other automotive components, Polyreflex delivers reliable, high-performance solutions.

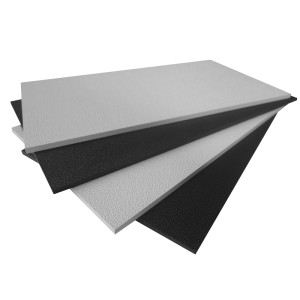

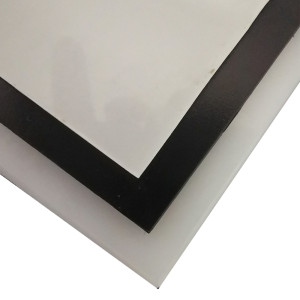

HDPE Sheet

HDPE sheet (High-Density Polyethylene sheet) is a durable and versatile thermoplastic material known for its high impact strength, excellent friction resistance, toughness, and low-temperature performance (-50ºC to 80ºC). It offers exceptional resistance to corrosion, mold, mildew, and rotting, making it highly durable in a wide range of environments. These outstanding properties make HDPE sheets ideal for various industries, including chemicals, machinery, electrical power, packaging, food processing, and more.

As a leading manufacturer of HDPE sheets in China, Polyreflex brings nearly 20 years of expertise to the production of high-quality HDPE sheets. We are a trusted supplier, offering products that meet rigorous standards for performance and durability, ensuring reliable solutions for our clients across multiple sectors. Whether you need customized sizes or specific material specifications, Polyreflex is committed to delivering top-notch HDPE sheets that meet the highest quality standards.

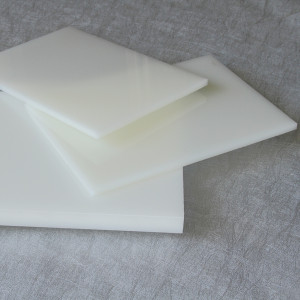

UHMWPE Sheet

UHMWPE (Ultra-High Molecular Weight Polyethylene) is a type of polyethylene with an average molecular weight exceeding 1.5 million. Compared to HDPE, UHMWPE offers superior properties, including exceptional wear resistance, high impact strength, excellent self-lubricating ability, and outstanding aging resistance. It maintains good toughness and mechanical strength even at liquid nitrogen temperatures. Its remarkable chemical and mechanical properties make UHMWPE sheets highly suitable for demanding applications across various industries, including power generation, marine, coke production, coal mining, paper, textiles, and chemicals.

Polyreflex, as a leading manufacturer of UHMWPE sheets in China, has nearly 20 years of experience in producing high-quality UHMWPE products. With a commitment to quality and innovation, we are proud to supply UHMWPE sheets that meet the rigorous standards of industries worldwide. Our expertise and advanced manufacturing processes ensure that our UHMWPE sheets deliver outstanding performance, durability, and reliability for even the most challenging applications.

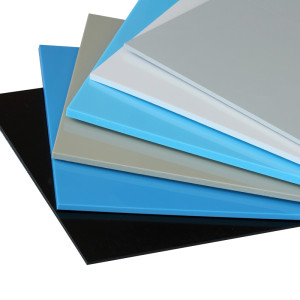

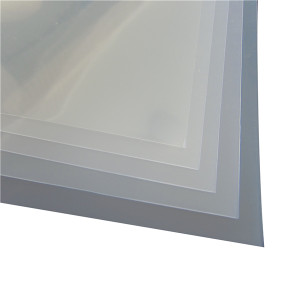

Polypropylene (PP) Sheet

Polypropylene (PP) is a versatile plastic widely used in both everyday life and industrial applications. As a type of thermoplastic, polypropylene can be processed into various products for different purposes through methods such as injection molding, extrusion, thermoforming, rotomolding, and foaming.

PP sheets offer several advantages, including high impact resistance, excellent heat resistance, and outstanding chemical stability. They are resistant to most acids, alkalis, salts, and oxidizing agents. Additionally, PP sheets are highly machinable and can be CNC cut, thermally bent, welded with PP rods, and butt welded. These properties make PP sheet an ideal material for the manufacturing of chemical equipment.

Polyreflex is a professional manufacturer specializing in polypropylene sheet extrusion and injection molding. We offer customized processing services, including CNC cutting, vacuum forming, welding, bending, and assembly. We typically keep common polypropylene sheets in stock. For special applications or performance-enhanced PP sheets, we can arrange custom production with a lead time of approximately 15 days. If you have any purchasing or processing requirements for PP sheets, please don't hesitate to contact us with your detailed needs. We will tailor and produce polypropylene sheets to meet the specific requirements of your application.

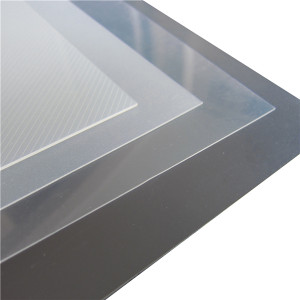

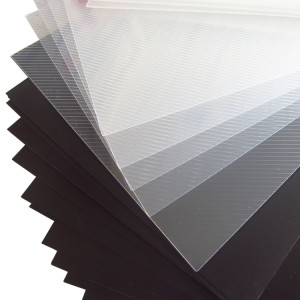

Polypropylene (PP) Film

Polyreflex polypropylene film sheet is a flexible, durable thermoplastic material made from non-toxic, odorless polypropylene through an extrusion process. Available in both sheets and rolls, PP film is highly versatile, offering excellent printability for offset printing, easy folding into boxes, and superior molding capabilities. These features make it a popular choice for packaging in industries such as food, cosmetics, toys, and electronics.

In addition to packaging boxes and signage, PP film is widely used in office supplies and stationery products, including file folders, document bags, notebook covers, and more. As a leading manufacturer of PP film in China with nearly 20 years of experience, Polyreflex is a trusted supplier of high-quality PP film. We also offer a comprehensive range of customization services for office products and packaging boxes, tailored to meet the specific needs of our customers.

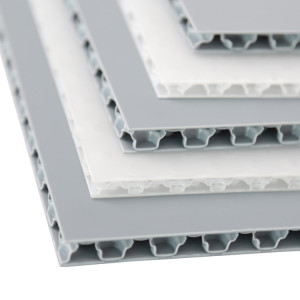

Construction Honeycomb Panel

Polyreflex polypropylene construction honeycomb panels are typically 15mm thick or more, featuring an upgraded structure compared to standard PP honeycomb panels. This design provides enhanced stability, superior strength, and excellent physical properties. The panels consist of four layers of polypropylene, including two flat surfaces and a unique double-layer honeycomb core. The result is an ultra-thick, lightweight plastic honeycomb board, specifically engineered for use in construction applications.

These ultra-thick honeycomb panels are widely used in China, particularly as backboards for porcelain or quartz countertops. Their combination of light weight and strength makes them ideal for providing support and stability. Additionally, their excellent insulation properties make them a great choice for wall panels and partitions.

Beyond their basic form as bare panels, these honeycomb panels are often laminated with various surface materials to enhance functionality, such as non-woven fabrics or leather. They are also gaining popularity in the automotive industry, where they are used for applications like the rear seat backboards and interior walls and ceilings of vans.

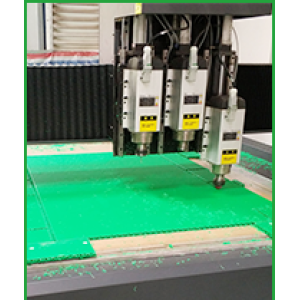

Custom & Processing Work

Polyreflex has strong custom and processing capacity. With advanced processing machines, special tools, clean and spacious space, excellent design team, skilled workers, we can meet various custom and processing requirements. Main processing works: CNC engraving, die-cutting, laser engraving, bending, sealing, gluing, printing, vacuum forming, injection molding, blow molding, assembly, etc.

- Name:

- Helen G

- Tel:

+0086-759-3320922

- Email:

- sale@polyreflex.com

- WhatsApp:

- 8613828266785

- Address:

- Room 1807, Phase 3 Cuidiwan, No.2 Junmin Rd, Zhanjiang, Guangdong, China