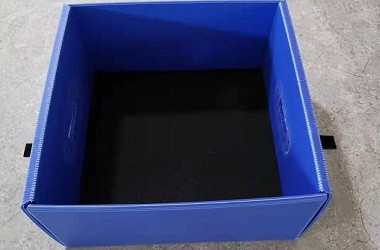

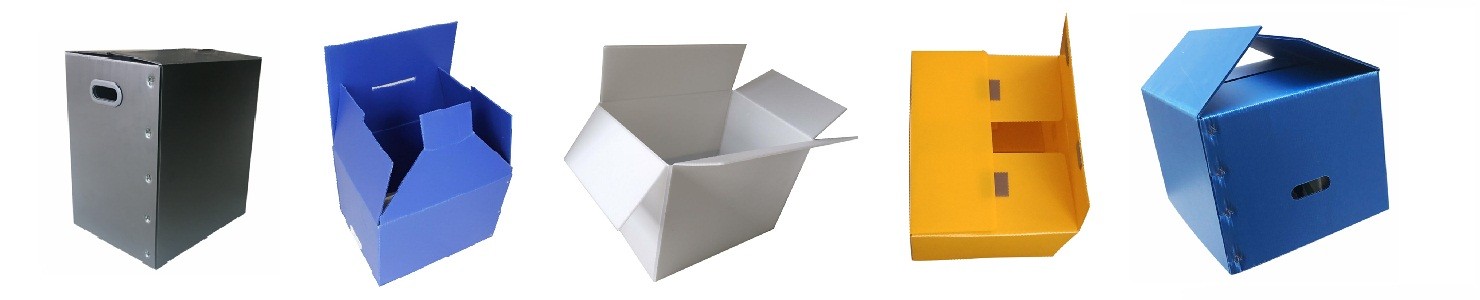

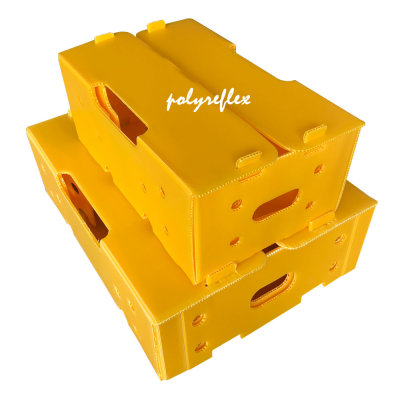

Polyreflex PP Hollow Packing Box for Electronics and Auto Parts

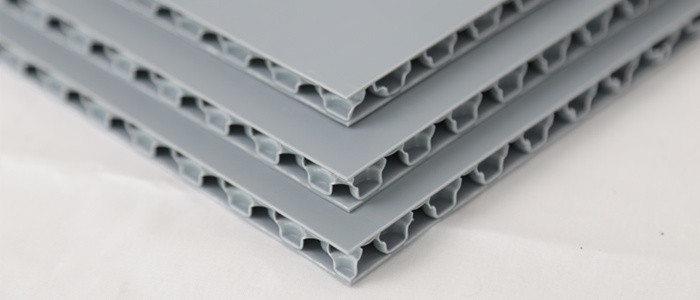

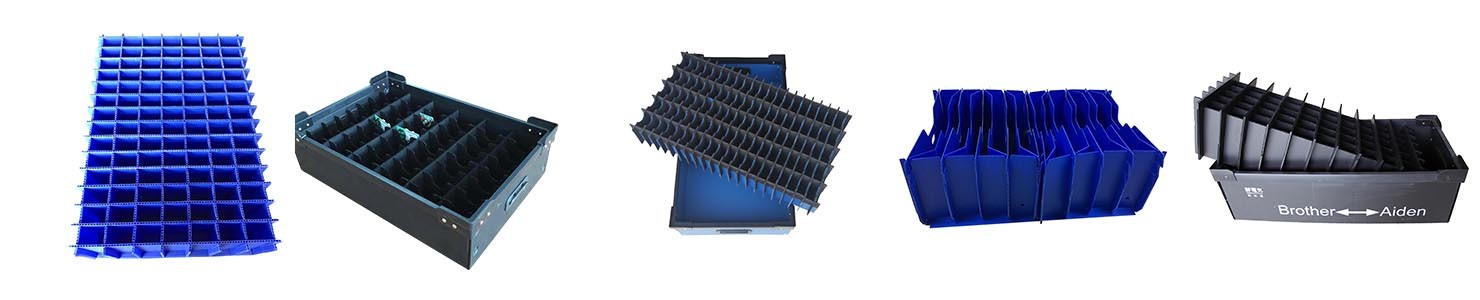

is made by plastic pp corrugated sheets and polypropylene honeycomb panels, these pp hollow boards can gain conductive and anti-static by adding the conductive masterbach or coat the anti-static oil.

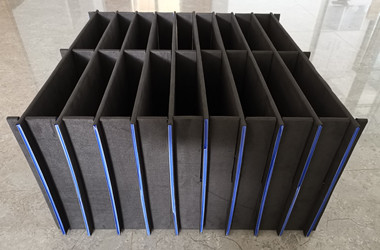

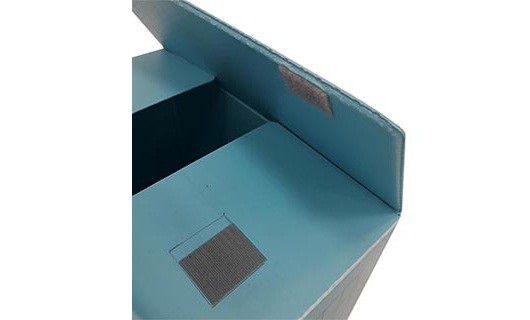

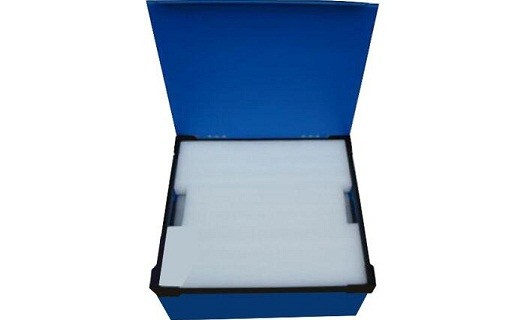

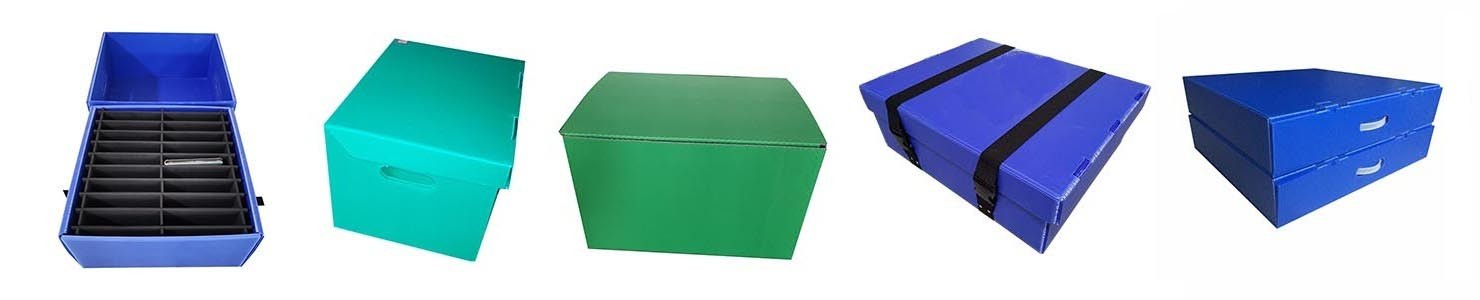

Plastic hollow boards with the advantages lightweight, durable, colorful, easy processing, waterproof..., they are ideal materials for packaging box for electronics, and by adding soft padding and flexible dividers, the electronic products in it can avoid bump.

Polyreflex electronics packaging box waterproof, moisture proof, better than carton box to protect electronic products.