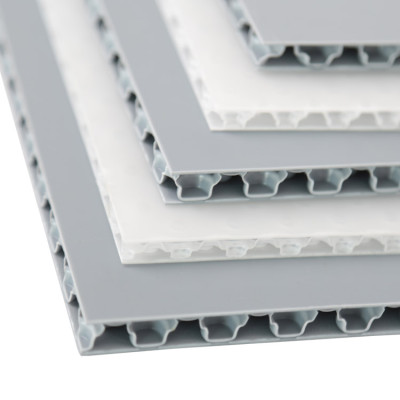

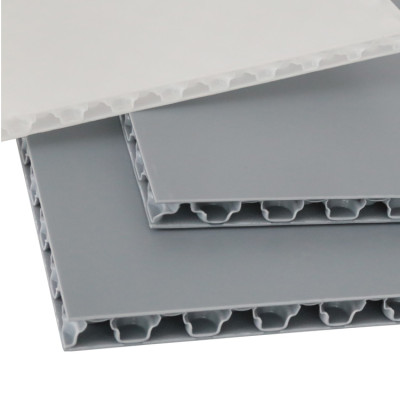

Polyreflex Polypropylene (PP) Honeycomb Panel

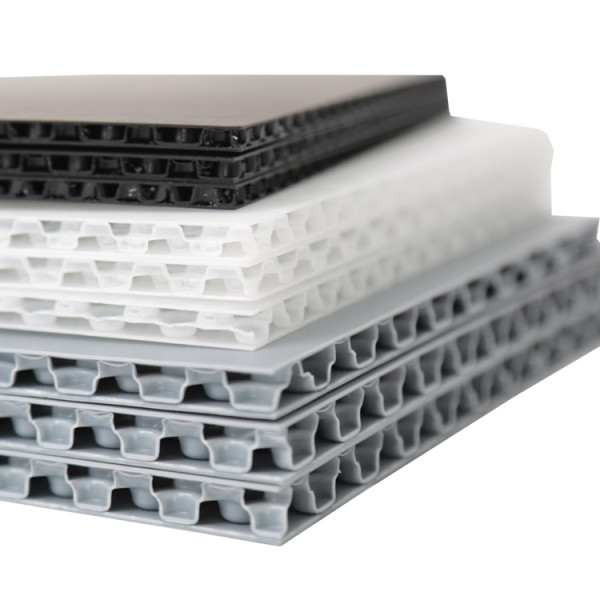

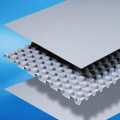

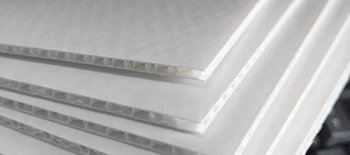

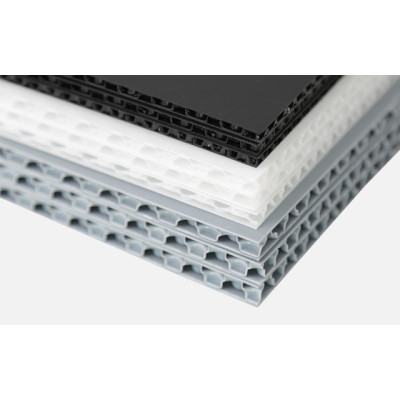

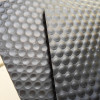

has a unique sandwich structure, in which the honeycomb structure is used as the core layer, and the single or double surface has a bubble finish or a flat finish.

Polyreflex plastic honeycomb board is made of polypropylene, with a stable honeycomb core layer structure, the polypropylene honeycomb panel has the advantages of lightweight, chemical resistance, impact resistance, high load capacity, easy processing and recyclability. Plastic honeycomb panels do not have the disadvantages of paper honeycomb panels that are not waterproof and easy to damp, nor do they have the shortcomings of high price, poor sound insulation, and poor corrosivity of aluminum honeycomb panels.

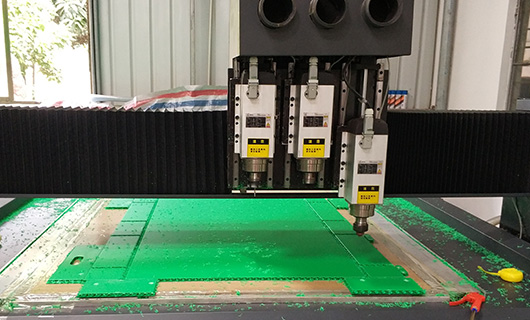

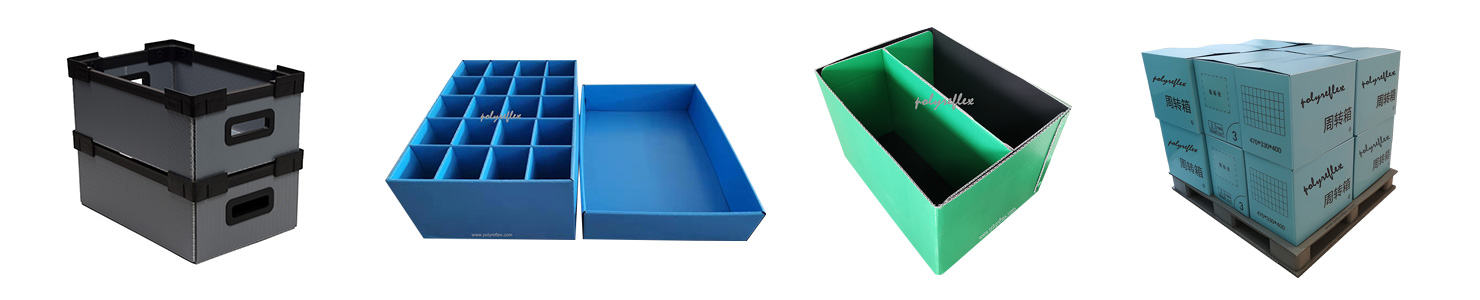

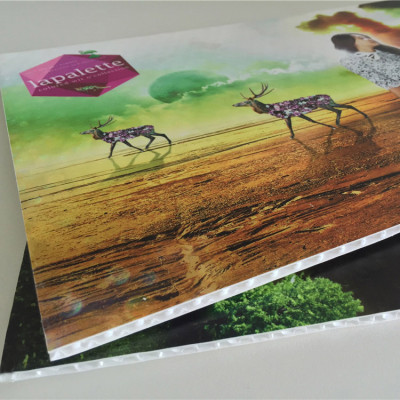

Lightweight polypropylene board is widely used in the automobile industry, logistics and transportation, warehouse and turnover management, packaging, advertising and display, construction, etc.