Why is ABS Sheet Considered an Ideal Material for Thermoforming?

Acrylonitrile Butadiene Styrene (ABS) sheets stand as a cornerstone in the realm of thermoplastics, revered for their versatility and utility across numerous industries. As a thermoplastic polymer, ABS boasts a unique composition characterized by a blend of acrylonitrile, butadiene, and styrene. This amalgamation yields a material renowned for its exceptional strength, rigidity, and impact resistance, making it a preferred choice for a myriad of applications.

In the world of manufacturing, thermoforming emerges as a pivotal process, pivotal in transforming thermoplastic sheets into various shapes and forms. ABS sheets, owing to their distinctive properties, have carved a significant niche in thermoforming applications. They exhibit a high degree of melt flow, rendering them pliable under heat, while retaining excellent moldability and dimensional stability. This intrinsic adaptability positions ABS sheets as a prime candidate for thermoforming processes across industries.

The purpose of this article is to delve into the myriad reasons why ABS sheets are universally acclaimed as the go-to material for thermoforming. By exploring their exceptional characteristics, advantages, and applications, we aim to elucidate the unparalleled suitability of ABS sheets in thermoforming processes. Through this exploration, readers will gain a comprehensive understanding of why ABS stands as an ideal material in the dynamic world of thermoforming.

What is ABS?

Acrylonitrile Butadiene Styrene (ABS) is a thermoplastic polymer renowned for its remarkable combination of properties, making it a highly sought-after material in numerous industries. ABS is composed of three primary monomers: acrylonitrile, butadiene, and styrene. This unique blend results in a polymer with exceptional strength, rigidity, and impact resistance, distinguishing it from other thermoplastics.

ABS's strength and durability stem from the presence of acrylonitrile, which enhances its structural integrity and resistance to deformation under stress. Meanwhile, butadiene contributes to ABS's toughness and impact resistance, making it capable of withstanding external forces without fracturing or breaking. Additionally, styrene imparts rigidity to ABS, ensuring dimensional stability and maintaining shape integrity over time.

The versatility of ABS is evident in its wide-ranging applications across various industries. From automotive components to consumer electronics, ABS is favored for its ability to meet diverse performance requirements. Its exceptional mechanical properties make it suitable for applications where strength, durability, and impact resistance are paramount.

Thermoforming Process

Thermoforming is a widely used manufacturing process that involves heating a thermoplastic sheet until it becomes pliable, then shaping it into a desired form using a mold. This versatile technique is employed across various industries for producing a vast array of products, ranging from packaging to automotive components.

The thermoforming process begins with the selection of a suitable thermoplastic material, such as ABS sheets, which are particularly well-suited for thermoforming applications. ABS sheets exhibit several properties that make them ideal for thermoforming:

1. High Melt Flow: ABS sheets possess a high melt flow index, meaning they can be heated to a temperature where they become soft and pliable, allowing for easy manipulation and forming into intricate shapes.

2. Excellent Moldability: ABS sheets demonstrate excellent moldability, enabling them to conform precisely to the contours of the mold with minimal distortion or deformation. This ensures that the final product retains its desired shape and dimensions accurately.

3. Dimensional Stability: ABS sheets maintain dimensional stability throughout the thermoforming process, ensuring consistent results and uniformity in the finished products. This property is crucial for applications where precise tolerances and tight specifications are required.

ABS sheets, with their high melt flow, excellent moldability, and dimensional stability, are well-suited for a wide range of thermoforming applications. Whether producing intricate automotive interior components, durable consumer goods, or custom packaging solutions, ABS sheets offer versatility and reliability, making them a preferred choice in thermoforming processes across industries.

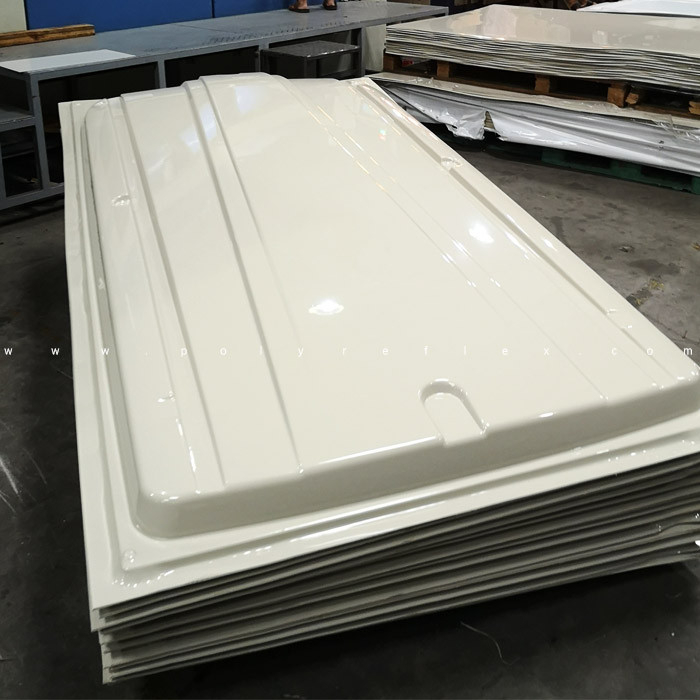

ABS Sheet Vacuum Forming

Comparisons with Other Materials

When considering materials for thermoforming applications, it's essential to compare ABS with alternative options commonly used in the industry, such as PVC and polycarbonate. Each material offers unique properties and advantages, but ABS stands out in several key areas, making it a preferred choice for many applications.

ABS vs. PVC

ABS vs. Polycarbonate

In summary, while PVC and polycarbonate have their own strengths and applications in thermoforming, ABS stands out for its balanced combination of impact resistance, surface finish, and recyclability. As a versatile and reliable material, ABS remains a preferred choice for many manufacturers across industries seeking high-quality thermoformed products.

Recyclability and Environmental Impact

ABS possesses recyclable properties, allowing it to be repurposed and reused in various applications. While ABS may not be as widely recycled as some other plastics like PET or HDPE, advancements in recycling technologies are expanding its recycling capabilities. When properly managed, ABS waste can be diverted from landfills and incorporated into new products, reducing the need for virgin materials and conserving valuable resources.

In comparison to certain materials, ABS offers distinct environmental advantages. For example, ABS's lower energy consumption during production and processing contributes to reduced greenhouse gas emissions compared to materials like polycarbonate. Additionally, ABS's durability and longevity in applications such as automotive components or electronic enclosures can extend the lifespan of products, further reducing environmental impact over time.

At Polyreflex, sustainability is a core value that guides our manufacturing practices and product offerings. Through innovative manufacturing processes and materials sourcing, Polyreflex ensures that our ABS sheets meet stringent environmental standards. We are dedicated to minimizing our environmental footprint and promoting eco-friendly solutions throughout our operations.

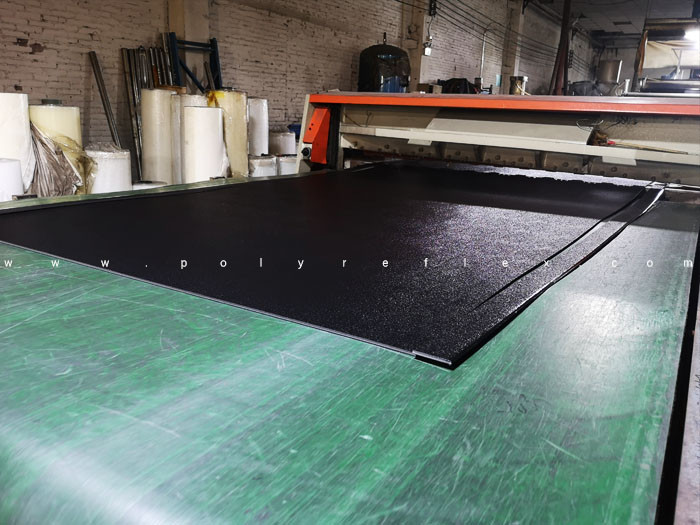

ABS Sheets Extrusion Production Line

ABS Automotive Front Bumper

In conclusion, the versatility and reliability of ABS sheets make them an indispensable material for thermoforming applications across a wide range of industries. ABS sheets offer numerous benefits, including cost-effectiveness, versatility in design, and exceptional mechanical properties, making them a preferred choice for manufacturers seeking high-quality thermoformed products. Whether producing automotive components, consumer electronics, or custom packaging solutions, ABS sheets from Polyreflex provide reliable performance and contribute to efficient and sustainable manufacturing processes.

Furthermore, at Polyreflex, we go beyond just supplying ABS sheets. We offer customized thermoforming services tailored to meet the specific needs of our customers. Our expertise in injection molding and vacuum forming allows us to provide precision-crafted thermoformed products, ensuring exceptional quality and consistency in every piece.

Choose Polyreflex for your thermoforming needs, and experience the unmatched quality and service that have made us a leader in the industry. With Polyreflex, customers can rely on not only high-quality ABS sheets but also expert guidance and support throughout the thermoforming process. Let us be your partner in shaping a brighter, more sustainable future through the power of ABS thermoforming.

- Discover Endless Possibilities with Polyreflex ABS Sheets

- Reach Out Now!