How PP Bubble Board is Used in Automotive Industry Applications

In the automotive industry, material innovation plays a key role in improving vehicle performance, safety, and sustainability. Among the many materials now gaining attention, PP Bubble Board stands out for its exceptional combination of lightweight strength, durability, and recyclability.

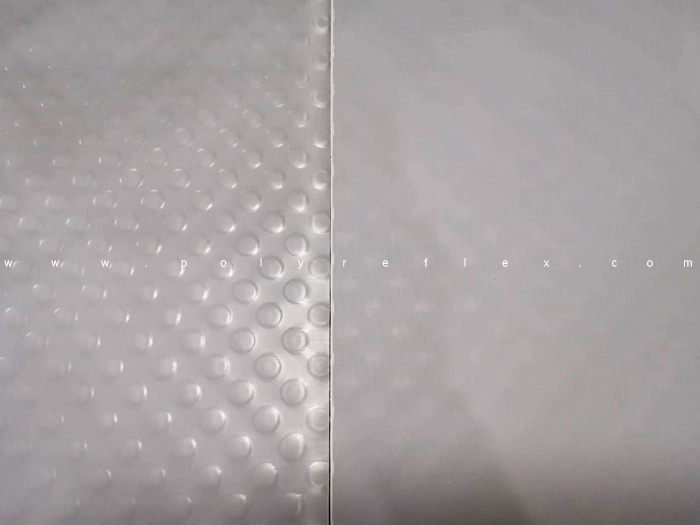

PP Bubble Board, also known as polypropylene bubble sheet, is a three-layer sandwich structure sheet made of polypropylene. It features a unique bubble-shaped core between two flat layers, giving it both rigidity and flexibility. With its excellent mechanical and environmental properties, PP Bubble Board is now widely used in automotive applications ranging from interior components to packaging for spare parts.

Why the Automotive Industry Chooses PP Bubble Board

Automotive manufacturers are constantly seeking ways to reduce vehicle weight, enhance durability, and adopt eco-friendly materials. PP Bubble Board perfectly meets these needs, offering several performance advantages:

Lightweight for Fuel Efficiency

The bubble core structure significantly reduces weight compared to solid plastic sheets or metal panels, helping to lower fuel consumption and emissions.

High Impact Resistance

Its multi-layered design absorbs shocks and vibrations, making it ideal for parts that need to withstand mechanical stress or repeated impact.

Moisture and Chemical Resistance

Polypropylene is naturally resistant to moisture, oil, and most chemicals, ensuring stable performance even in harsh automotive environments.

Eco-Friendly and Recyclable

PP Bubble Board is 100% recyclable and free from heavy metals or halogens, supporting the global shift toward sustainable manufacturing.

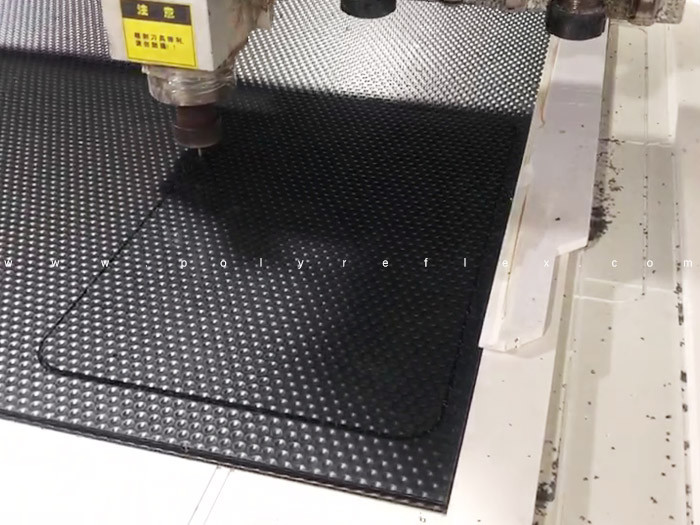

Easy Processing and Versatility

The material can be cut, thermoformed, laminated, or printed, enabling manufacturers to create custom parts efficiently.

Main Applications of PP Bubble Board in the Automotive Industry

PP Bubble Board's versatility allows it to serve in multiple areas of automotive production and logistics. Below are its most common and impactful applications:

1. Automotive Interior Panels

PP Bubble Board is often used in door panels, trunk liners, ceiling boards, and floor panels.

Its lightweight nature contributes to overall vehicle weight reduction, while its sound absorption properties enhance cabin comfort. It can also be laminated with fabric, leather, or decorative films to achieve an aesthetic finish suitable for car interiors.

2. Trunk and Luggage Compartment Components

For trunk covers, side panels, and under-tray partitions, PP Bubble Board offers an excellent stiffness-to-weight ratio.

It provides good load-bearing performance, resists deformation, and maintains shape even under temperature fluctuations.

3. Protective Packaging for Automotive Parts

During production and supply chain transport, automotive parts such as electronic modules, lamps, or dashboards need secure and reusable packaging.

PP Bubble Board is ideal for returnable boxes, partitions, and trays, offering shock absorption, moisture protection, and scratch resistance. Anti-static versions can also prevent ESD (electrostatic discharge) damage.

4. Underbody Shields and Protective Covers

Its resistance to moisture, oil, and dirt makes PP Bubble Board suitable for underbody shields, wheel well covers, and protective barriers.

These components help extend the service life of vehicles and contribute to better protection against environmental factors.

5. Thermoformed Automotive Components

The material can be thermoformed into 3D shapes, allowing for structural or decorative applications.

Manufacturers use it to create custom parts such as molded side panels, insulation boards, and door inserts that meet specific design requirements.

PP Bubble Board vs Other Automotive Materials

When compared with traditional automotive materials, PP Bubble Board demonstrates a superior balance between strength, cost, and sustainability.

| Material | Weight | Impact Resistance | Moisture Resistance | Recyclability | Cost |

PP Bubble Board | ⭐ Ultra-light | ⭐⭐ High | ⭐⭐ Excellent | 100% recyclable | Moderate |

| Solid PP Sheet | Medium | High | Excellent | Recyclable | Higher |

| Cardboard | Light | Low | Poor | Recyclable | Low |

| ABS / PVC Sheet | Heavy | High | Good | Limited | Higher |

Conclusion: PP Bubble Board provides the best balance of performance and sustainability, making it the preferred choice for lightweight automotive solutions.

Customization Options from Polyreflex

With 18 years of manufacturing experience, Polyreflex specializes in providing customized PP Bubble Board solutions for automotive manufacturers and packaging suppliers worldwide.

We offer:

Each PP Bubble Board can be customized according to customer specifications to meet various automotive production and logistics requirements.

As the automotive industry continues to evolve toward lightweight, sustainable, and high-performance materials, PP Bubble Board proves to be an exceptional solution. It combines strength, versatility, and environmental responsibility, offering manufacturers a reliable alternative to heavier or less durable materials.

With advanced production technology and a deep understanding of automotive needs, Polyreflex delivers high-quality PP Bubble Boards trusted by automotive clients around the world.

Contact Polyreflex today to discover how our PP Bubble Board can enhance your automotive components and packaging solutions.