Excellent Formability Custom Size ABS Plastic Sheet for Auto Parts

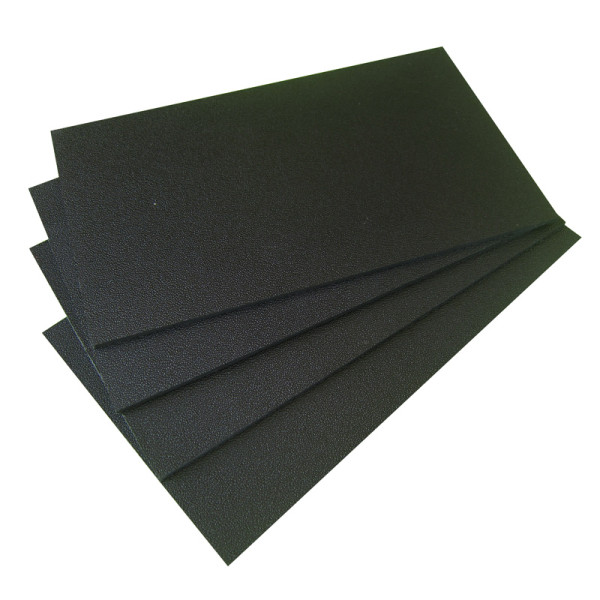

Polyreflex ABS Plastic Sheet

- High Impact Strength & Durability

- Excellent formability

- Corrosion Resistance

- Description

- Specifications

- Surface Type and Texture

- Processing Service

- Thermoforming Service

- Uses

Description

High Impact Strength

ABS sheet is considered to a stronger material with the structure. This makes it an ideal choice for various applications, which needs strong and stiff plastic that is resistant to external strength impacts.

Excellent Formability

Polyreflex thermoplastic ABS plastic sheet has a relatively low melting point, which means it can be easily melted and thermoformed into different shapes by vacuum forming.

Excellent Chemical Properties

ABS panel has the characteristics of corrosion resistance, chemical resistance and high temperature resistance, which allow the finished plastic to withstand adverse environmental conditions.

Flexiable Physical Properties

ABS plastic sheet has excellent performance in terms of structural stability and dimensional stability, abrasion and stain resistance. Good surface brightness and color allow the material to be used directly.

Easy Processing

Drilling, milling, sawing, laser cutting or CNC engraving all these processes can be carried out easily with ABS sheet easily.

Specifications

| Thickness | 0.8mm - 2.5mm | 3mm - 25mm | 30mm - 100mm | 105mm - 230mm | |

|---|---|---|---|---|---|

| Size | 1000 x 2000mm, 915 x 1830mm, 1220 x 2440mm in stock, other size can be customized. |

1000 x 2000mm in stock, other size can be customized. | 1000 x 1220mm in stock, other size can be customized. | 1000 x 2000mm in stock, other size can be customized. | |

| Density | 1.06 - 1.1 g/cm3 | ||||

| Surface | Smooth, various texture options | ||||

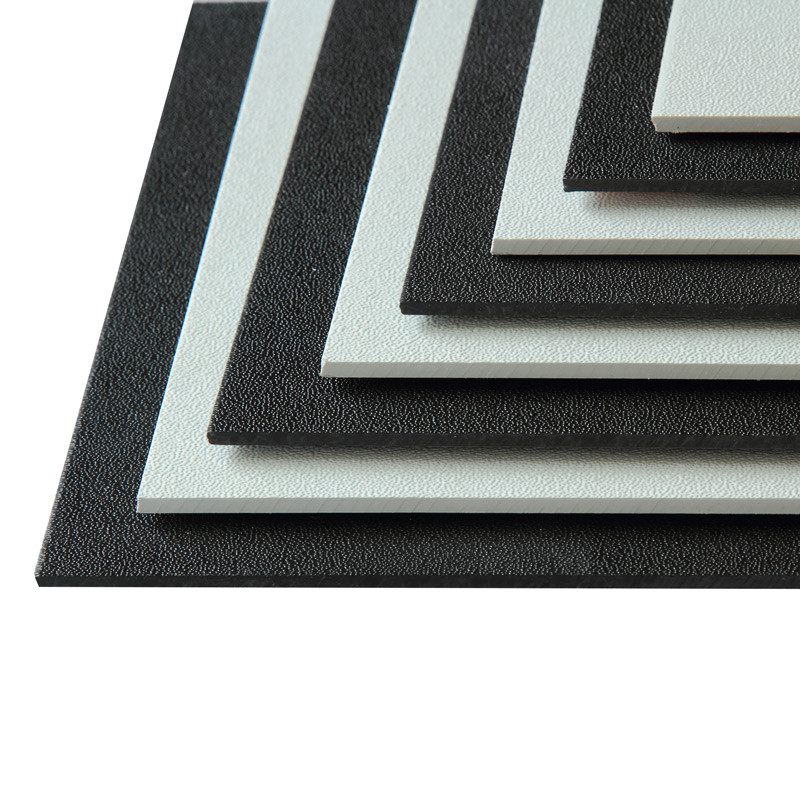

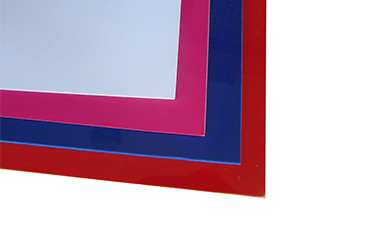

| Color | Grey, black and white are the standard colors, custom colors are available. | ||||

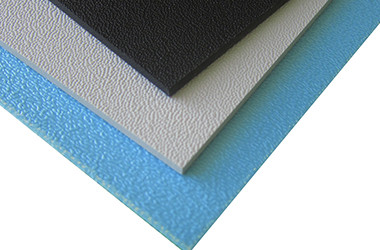

Surface Type

Smooth surface

High glossy surface

Smooth and texture surface

Texture surface

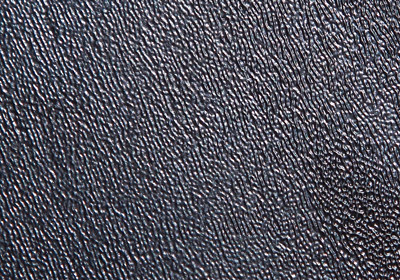

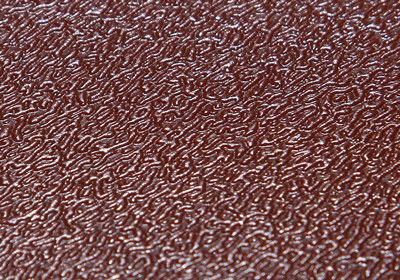

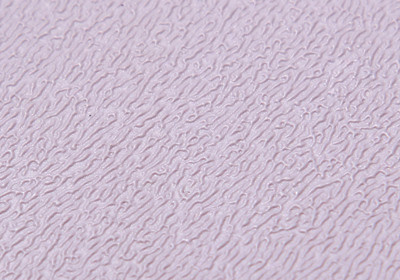

Texture Options

Texture-PR001

Texture-PR002

Texture-PR003

Texture-PR004

Texture-PR005

Texture-PR006

Texture-PR007

Texture-PR008

Processing Service

25mm - 50mm ABS board for CNC machining

ABS mechanical parts

ABS spare parts for industrial use

3mm - 5mm ABS sheet for vacuum forming

2.5mm - 4mm ABS sheet vacuum blister into luggage

ABS shallow tray / plate

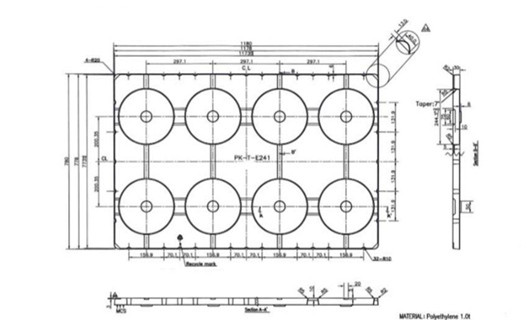

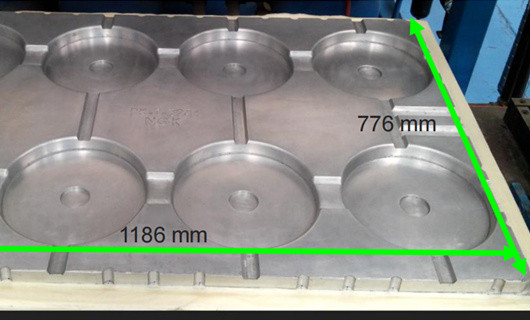

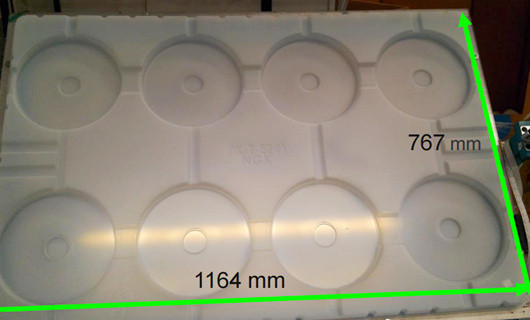

Thermoforming Service

Polyreflex provides thermoforming service

Send us drawings and we make the mould

Thermoformed customized ABS products

Heat to soften ABS sheet

Blistering of ABS sheet

Vacuum the air between the ABS and mould

The Use of ABS Sheet

Automotive Used Interior and Exterior

Polyreflex ABS sheet is lighter than other plastics, vehicles using ABS sheet can reduce vehicle weight by 10%, which can be more fuel efficient.Typically, ABS sheets are used for wheel covers, dashboards, trims, trunk storage basin, dashboards, trims and body parts due to their strength, low temperature resistance, and rough surfaces that are not easy to scratch.

Vehicle Industry

Polyreflex ABS plasltic sheet has a high impact resistance and durability, that makes ABS sheet is a ideal for specific applications such as high-speed train carriage, mini-bus, RV, public transit vehicles and other transportation industry needs.

Advertising Billboard & Decorative Displays

With the characteristics of thermoplasticity, flexibility and ductility, Polyreflex ABS sheet can be molded into specific shape with varied colors, in addition to being very durable. The vacuum formed ABS products lamilated with PMMA or PC material on the surface can be used outdoor advertising displays without fading or scratching.

Refrigeration Industry

Another advantage of ABS sheet compared to other plastic sheets is low temperature resistance, so it is widely used in refrigeration industry, such as refrigerator liners, cold storage room panel.

Household Appliances Exteriors

ABS ranks first in the amount of plastics used in household appliances. Good surface brightness, easy painting, coloring and processing make ABS become the shell material of various home appliances.

Engineering Applications

As the most common thermoplastic engineering plastic, ABS sheet is also used as mechanical gears, bearings, and various knobs.

Luggage, Office Supplies, Toys

ABS plastic sheet has the strength and flexibility are both desired, luggages is the example. ABS is non-toxic and harmless, so it's a safe plastic product for making toys and similar products.

- Are you a trading company or a manufacturer?

- more>

Polyreflex is a professional manufacturer with more than 15 years experiences, with five production sites located in China and one production site located in Vietnam.

- Can you cut to size or print or thermoform?

- more>

Of course we can. Polyreflex processing center has a variety of advanced processing equipment, and a well-trained and experienced technical team to meet the customized needs of customers, such as cutting, machining, vacuum forming, injection molding, blow molding, assembly, etc.

- What is the payment method?

- more>

T/T, L/C, PayPal, Western Union payment are available. Polyreflex is an Alibaba certified supplier, and it is also okay to place an order through Alibaba. https://polyreflex-cn.en.alibaba.com/

- What is the lead time?

- more>

Usually 15 to 20 days. The specific lead time is best to be confirmed after letting us know the order details. We have stock of plastic sheets to meet urgent needs, and we can also advance the delivery time for customers according to the production condition.

- Name

- *Title

- *Content

- Name:

- Helen G

- Tel:

+0086-759-3320922

- Email:

- sale@polyreflex.com

- WhatsApp:

- 8613828266785

- Address:

- Room 1807, Phase 3 Cuidiwan, No.2 Junmin Rd, Zhanjiang, Guangdong, China