In the mechanical parts industry, materials used for manufacturing components must withstand rigorous physical demands, including high levels of abrasion, impact, and exposure to various chemicals. Polyreflex's range of plastic sheets, such as ABS, HDPE, UHMWPE, and PP sheets, are designed to meet these challenges, offering solutions that ensure durability, long service life, and cost-effectiveness. These materials provide a viable alternative to traditional metals due to their lightweight properties, ease of fabrication, and corrosion resistance. Industries such as construction, heavy machinery, and automotive heavily rely on these materials for producing essential mechanical components like protective covers, pads, liners, and structural parts.

UHMWPE (Ultra-High-Molecular-Weight Polyethylene) sheets are widely utilized in the mechanical industry for applications demanding extreme wear resistance and impact strength. A key example is their use in crane outrigger pads, which must endure significant pressure from heavy machinery while distributing the load. UHMWPE sheets excel due to their high load-bearing capacity, allowing them to support heavy weights without deformation. Their low coefficient of friction enhances stability, preventing slippage under dynamic conditions.

Additionally, UHMWPE sheets offer excellent chemical resistance, making them suitable for various outdoor environments. These pads withstand exposure to oils, solvents, and harsh weather without degrading, ensuring effectiveness over time. Thus, UHMWPE sheets are a preferred choice for crane outrigger pads, delivering safety and longevity in demanding applications.

ABS (Acrylonitrile Butadiene Styrene) sheets are widely used in manufacturing protective machine guards and housings due to their impact resistance and toughness. This material withstands external impacts, making it ideal for enclosures that protect sensitive mechanical parts from dust and debris. The lightweight nature of ABS simplifies handling during installation and reduces the weight of machinery. Its excellent machinability allows for easy cutting and assembly, enabling manufacturers to produce tailored enclosures.

In addition to practical benefits, ABS offers a visually appealing surface finish suitable for both functional and aesthetic purposes. Its ability to be thermoformed into complex shapes allows for customized covers that meet the diverse needs of industries like automotive and electronics. With its combination of durability and versatility, ABS sheets are a preferred choice for machine guards that enhance safety and contribute to industrial design.

Wear resistance

High impact strength

Lightweight

Chemical resistance

Corrosion resistance

Low maintenance

100% recyclable

Customizable sizes

Cost-effective

UHMWPE sheets used to produce crane outrigger pads, providing excellent load distribution and impact resistance for heavy-duty applications.

ABS sheets thermoformed into protective housing for industrial machines, ensuring durability and safety while maintaining a clean aesthetic.

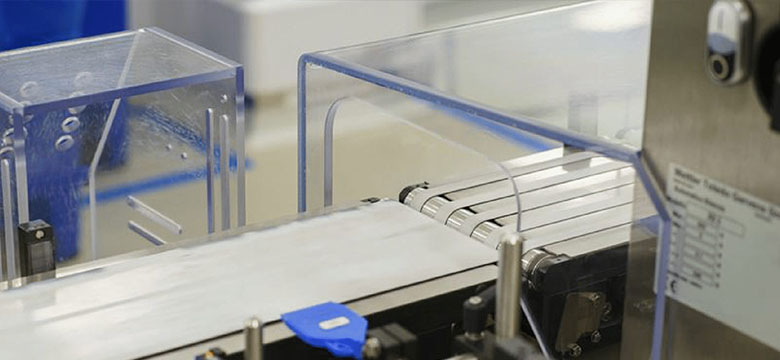

HDPE sheets used as wear-resistant liners in conveyor systems, reducing material buildup and minimizing wear on machinery components.

UHMWPE sheets or HDPE sheets are used to manufacture wear-resistant components, such as gears, in machinery. These materials provide excellent durability, impact resistance, and low friction, making them ideal for extending the service life of mechanical parts subjected to constant wear and tear.

- Name:

- Helen G

- Tel:

+0086-759-3320922

- Email:

- sale@polyreflex.com

- WhatsApp:

- 8613828266785

- Address:

- Room 1807, Phase 3 Cuidiwan, No.2 Junmin Rd, Zhanjiang, Guangdong, China